骨灰珠宝设备:骨灰如何制作人工钻石

- 电阻炉名称:骨灰珠宝设备:骨灰如何制作人工钻石

- 电阻炉类型:骨灰晶石设备

- 电阻炉厂家:西格马骨灰晶石设备

- 电阻炉规格:

- 电阻炉温度:1000℃、1200℃、1400℃℃

骨灰珠宝设备需要哪些?骨灰如何制作人工钻石?制作人工钻石一般需要高温烧结提纯、热压成型、抛光成型。

Diamond Formation Theory金刚石形成理论

Diamonds grow in extreme high-pressure and high-temperature (HPHT) environments in the Earth’s mantle, 95–155 miles (150–250 kilometers) below the Earth’s surface.

钻石生长在地球表面以下95-155英里(150-250公里)的地幔中的极端高压和高温环境中。

SAINTER laboratory recreates this natural process of HPHT (3,000ºK, 60,000 Bar) and transforms the carbon from your loved one’s remains into real diamonds.

圣特瑞实验室重现了这种HPHT(3000ºK,60000 Bar)的自然过程,并将你爱人遗体中的碳转化为真正的钻石。

Chemical Element Carbon化学元素碳

Turning ashes or hair into diamonds is possible because carbon comprises about 19% of the human body, and diamonds are carbon in a crystal form. Cremation diamonds are real diamonds that are grown thanks to the carbon present in human remains (hair and cremation ashes).

把灰烬或毛发变成钻石是可能的,因为碳约占身体的19%,而钻石是晶体形式的碳。人工钻石是由于人类遗骸(毛发和人工灰烬)中的碳而生长的真正钻石。

Nitrogen is also present in the human body, but it makes up only about 3% of the body. This element gives the memorial diamond a yellow color, which varies from a light yellowish tone to a dark orange.

氮也存在于身体内,但它只占身体的3%左右。这种元素使纪念钻石呈现黄色,颜色从浅黄色到深橙色不等。

We also produce colorless cremation diamonds by removing the nitrogen from the carbon before the crystallization process begins.

我们还通过在结晶过程开始前从碳中除去氮来生产无色的火化钻石。

How Create Cremation Diamonds 骨灰如何创造人工钻石

Different manufacturing processes require different equipment. According to their own process can choose different temperature furnace and whether pressure treatment.

不同的制作工艺,需要的设备不一样。根据自身工艺可选择不同温度的炉型与是否加压处理。

STAGE ONE 一第阶段

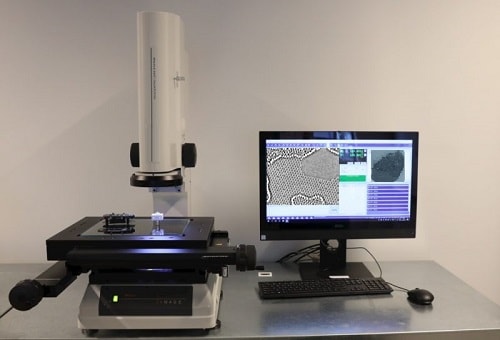

Material Inspection材料检验

The first stage is to analyze your loved ones’ remains to determine if they contain the right amount of carbon to create a diamond. The amount of carbon present in the remains differs, and there may be a slight chance that there is not enough carbon for our company’s creation procedure. We usually suggest our customers provide extra hair samples to keep them as a backup plan.

一第步是分析你所爱的人的遗骸,以确定他们是否含有制造钻石所需的适量碳。遗骸中的碳含量各不相同,可能有一点可能是我们公司的创作程序中没有足够的碳。我们通常建议我们的客户提供额外的毛发样本,以备不时之需。

In this stage, we work with an element analyzer to determine the amount of carbon present in the remains.

在这一阶段,我们使用元素分析仪来测定遗体中的碳含量。

化学分析

STAGE TWO第二阶段

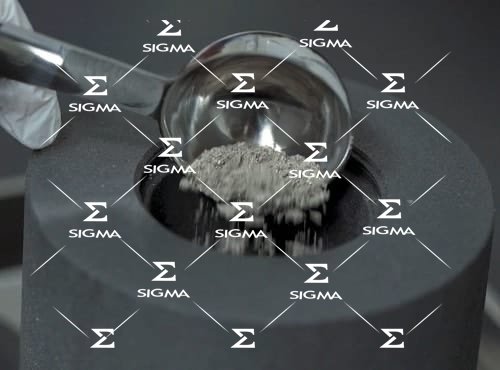

Nano Crystallization

纳米结晶

We mix an impurity remover with a particular solvent to extract unstable chemical particles. The remains (hair and ashes) are ground and then stirred into a micro powder while in a chemical gas atmosphere. Our impurity remover will attach itself to any impurity it finds, which will then be isolated during the centrifuge process. We also apply a few technicalities to keep the carbon rightfully stored, with any other elements being diminished to the minimum.

我们将杂质去除剂与特定溶剂混合,以提取不稳定的化学粒子。遗体(毛发和灰烬)被磨碎,然后在化学气体气氛中搅拌成微粉。我们的杂质去除剂会附着在它发现的任何杂质上,然后在离心过程中分离出来。我们还应用了一些技术手段来保持碳的合理储存,同时将其他元素减少到设计低限度。

The grinding process can be compared to the Earth’s motions: rotation and revolution.

研磨过程可以比作地球的运动:自转和公转。

高温烧结模具

SGM 超高温烧结提纯炉

STAGE THREE第三阶段

Vacuum Purification at Extreme Temperatures

极端温度下的真空净化

In this stage, the now-purified material gets heated to high temperatures so that any extra impurities can be eliminated. In this process, oxygen is expunged, and other protective gasses are introduced to keep the remains from oxidizing. Then, we apply double handling for the chemical extraction. Sometimes, we need to apply a high voltage in an airtight canister to purify the carbon even more.

在这个阶段,现在纯化的材料被加热到高温,以便任何额外的杂质可以被消除。在这个过程中,除去氧气,并引入其他保护气体,以防止残余物氧化。然后,我们对化学萃取采用双重处理。有时,我们需要在密封罐中施加高压,以进一步净化碳。

We usually use a gas mix to preserve the remains from oxidizing.

通常用混合气体来保护残留物不被氧化。

STAGE FOUR第四阶段

Soaked-chemical Carbon Purifying Process

浸渍化学碳净化工艺

The extracted carbon is taken into a resistant case in a wet, chemical atmosphere to boost the levels of purity. The software-controlled process controls the temperature, stirring speed, and extra chemical agents to ensure the quality of the carbon. In this final purification stage, the purity will reach a 99.99% level.

提取出来的碳被带到一个潮湿的化学环境中的耐腐蚀的箱子里,以提高纯度。软件控制的过程控制温度,搅拌速度和额外的化学试剂,以确保碳的质量。在设计后的纯化阶段,纯度将达到99.99%。

the purified carbon is the essence of the whole crystallization process. During this stage, oxygen and water are removed to make sure the carbon gets purified to its maximum level.

纯碳是整个结晶过程的精华。在这个阶段,氧气和水被去除,以确保碳被净化到设计水平。

The water is purified with an ultrapure system down to 18 MΩ.cm (1.3 times purer than normal drinking water). Every chemical container we use is cleaned with this ultrapure system to avoid any external impurities from entering the process.

水通过超纯系统净化至18MΩ.cm(比普通饮用水纯净1.3倍)。使用的每一个化学容器都用这个超纯系统进行清洁,以避免任何外部杂质进入过程。

STAGE FIVE第五阶段

High-Pressure High-Temperature Crystallization

高压高温结晶

The HPHT crystallization process transforms the purified carbon atoms into a genuine diamond.

高温高压结晶过程将提纯的碳原子转变成真正的钻石。

In this stage, the purified carbon we got from the remains is turned into flake graphite in the shape of a cylinder. This cylinder is encased in protective elements, preparing the carbon for the final stages where pressure, insulation, temperature control, and protection will be required.

在这一阶段,我们从遗体中提取的纯净碳变成了圆柱形的片状石墨。这个钢瓶被包裹在保护元件中,为需要压力、绝缘、温度控制和保护的设计后阶段准备碳。

The crystallization process can take a modest number of days or sometimes months to complete; it all depends on the size and color of the cremation diamond.

结晶过程可能需要几天甚至几个月才能完成;这完全取决于人工钻石的大小和颜色。

超高温热压

西格马钻石高温热压炉

STAGE SIX第六阶段

Diamond Refinement

金刚石精炼

Our rough cremation diamonds get mixed using graphite, especially on their outer surfaces. These diamonds then get polished by experts who only work with our created diamonds.

粗糙的火化钻石混合使用石墨,特别是在其外表面。进行钻石处理、抛光成型。

厂家品牌不一样,价格也有所差别。另外,需要根据详细参数才能确定, 影响骨灰珠宝设备:骨灰如何制作人工钻石价格因素有:电炉材质、骨灰珠宝设备:骨灰如何制作人工钻石炉膛尺寸、骨灰珠宝设备:骨灰如何制作人工钻石额定温度、真空度、电子仪表等综合配置需求。请咨询洛阳智能马弗炉厂家获取骨灰珠宝设备:骨灰如何制作人工钻石详细技术与价格

联系我们

联系我们

洛阳智能高温电炉全国咨询热线

洛阳智能高温电炉全国咨询热线

在线客服

在线客服